Assembling each hexagonal flower.

Assembling each hexagonal flower. Six 3D pentagons, get linked together with aluminum jump rings by hand, very time consuming!

Battenfield Injection Molding Machine:

Battenfield Injection Molding Machine: with my aluminum mold in the mud base! Ready to mold!

Part 1 of 2 part mold... just CNCed to gleaming perfection! *

Part 1 of 2 part mold... just CNCed to gleaming perfection! * Running the 4 hour long HAAS (CNC) program to mill out part 1 of the mold.

Running the 4 hour long HAAS (CNC) program to mill out part 1 of the mold.Lots and lots of coolant! Cleaning this up is a nightmare! One smells like coolant for at least 24 hrs after!

Ran the Hass program on a piece of Modulan, a dense pink foam, very east to machine.

Ran the Hass program on a piece of Modulan, a dense pink foam, very east to machine.A good way to test your code and make sure there are no errors in the CNC milling process.

Bridging the gap between design and manufacturing: PROTOTYPING

Bridging the gap between design and manufacturing: PROTOTYPINGWax pour (green) and FDM 3D print (white) from CAD files to test scale and shape. Its nice to be able to touch something you've created only in virtual space!

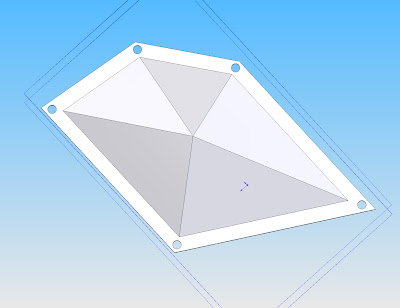

Solidworks: CAD mold bottom

Solidworks: CAD mold bottom Solidworks: CAD mold top

Solidworks: CAD mold top Solidworks: CAD pentagon design

Solidworks: CAD pentagon design

POLYSCAPE proposal image!